By Eric Sampson

Since we here in Central Colorado have been singled out as a bicycle mecca, we thought we’d take a closer look at this enigmatic machine. First, consider what life may have been like at the dawn of the 19th century. Most in the community lived and worked on local farms, some distance from the town center. For community events, folks would come to town by horse. After trading for some staples, a meal and perhaps a nip of apple wine, some sport could be had by racing horses around the square. A little money would change hands, along with the entertainment, and the social machinery was oiled for another day. As towns grew, and the square shrank the horse, fine fellow that he is, could become a nuisance – hard to house break, and quite willing to share his flies. Best to leave him at the livery stable.

But what about sport? Or status? What came about was the hobby, or dandy horse. At first it was simply a board supported by two wheels and propelled by the rider pushing the ground with his feet. Some were carved and decorated to resemble a horse, and early models had no steering. In the early 1800s, models became available with steering around a vertical axis. First patented by Baron von Drais in France in 1818, steering was the first major advance in cycle design. The steerable dandy horse also demonstrated an ergonomic principle. Freed from supporting your body weight, the legs could do much more work. “The swiftness with which a person well practiced can travel is almost beyond belief. Eight, nine and even 10 miles may, it is asserted, be passed over within the hour on good level ground,” is how Ackermann’s Magazine put it in 1819. In 1839 a Scottish blacksmith, Kirkpatrick Macmillan, introduced the “self-balancing” machine by inclining the steering angle. In this arrangement, the point of contact of the front wheel lies somewhat behind the projected center line of the steering axis. Called “trail” in cycles, and “caster” in autos, a slight self-centering is obtained by this arrangement, which frees the rider from actively having to steer a straight line.

But what about sport? Or status? What came about was the hobby, or dandy horse. At first it was simply a board supported by two wheels and propelled by the rider pushing the ground with his feet. Some were carved and decorated to resemble a horse, and early models had no steering. In the early 1800s, models became available with steering around a vertical axis. First patented by Baron von Drais in France in 1818, steering was the first major advance in cycle design. The steerable dandy horse also demonstrated an ergonomic principle. Freed from supporting your body weight, the legs could do much more work. “The swiftness with which a person well practiced can travel is almost beyond belief. Eight, nine and even 10 miles may, it is asserted, be passed over within the hour on good level ground,” is how Ackermann’s Magazine put it in 1819. In 1839 a Scottish blacksmith, Kirkpatrick Macmillan, introduced the “self-balancing” machine by inclining the steering angle. In this arrangement, the point of contact of the front wheel lies somewhat behind the projected center line of the steering axis. Called “trail” in cycles, and “caster” in autos, a slight self-centering is obtained by this arrangement, which frees the rider from actively having to steer a straight line.

The next great advance, the crank, has a disputed lineage. The crank is generally attributed to the Frenchman Pierre Lallement, who patented cranks on the front wheel in 1866, leading to the French velocipede, or bone shaker. Perhaps the confusion revolves around the front wheel, because as Messrs. Macredy and Stoney write in The Art and Passion of Cycling, “To Scotland, it appears, belongs the honor of having first affixed cranks to the bicycle; and still stranger to relate, it was not to the “hobby horse” but to a low-wheeled rear driver machine, the exact prototype of the present day safety. The honor of being the inventor has now been fixed on Kirkpatrick, M’Millan (sic), of Courthill, Dumfriesshire.”

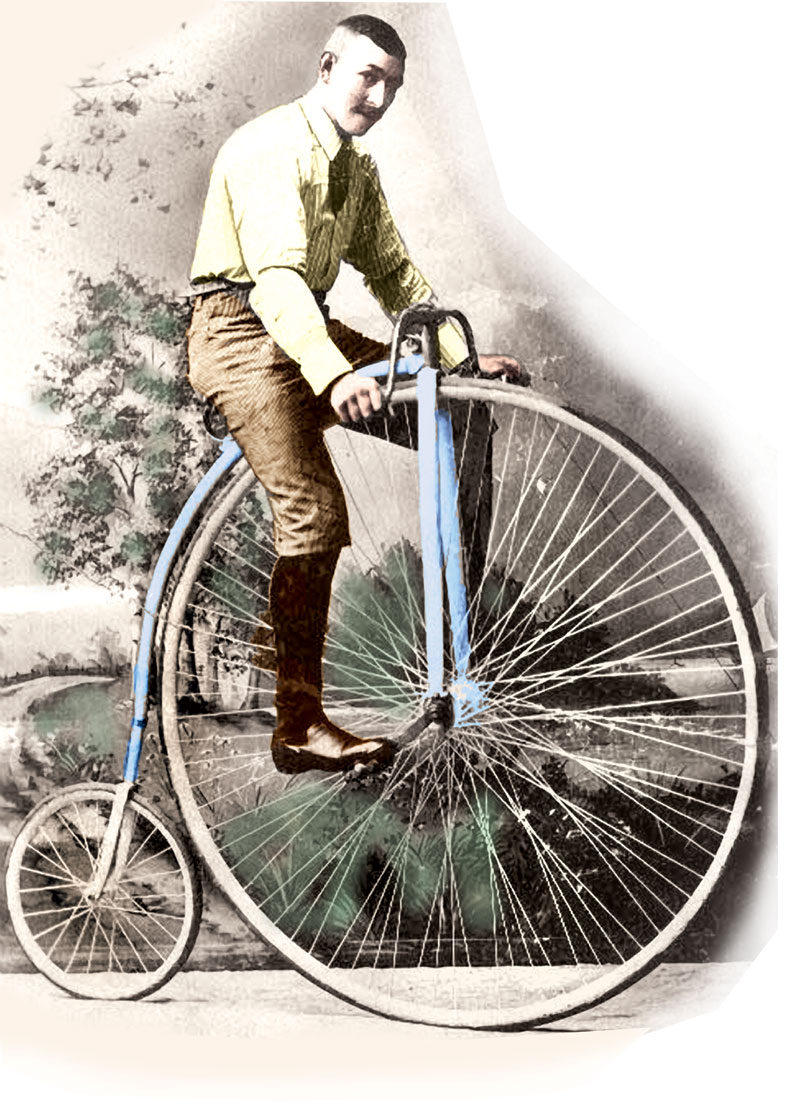

This machine had cranks in the normal position of today, linked by tie rods to cranks fitted to the rear wheel. Such an arrangement can’t be geared up or down. The ratio is still the size of the driven wheel. Perhaps because of the greater ease of increasing the size of the driven front wheel, cycling history followed the bone-shaker. A bone-shaker used wooden wheels patterned after wagon wheels, but lighter and fitted with an iron tire. The frame and forks were usually wood, or iron-bound wood. It all added up to a heavy, not very smooth-running vehicle. As mechanics became more familiar with metals, wrought iron gave way to steel. Even early steels, primitive compared to today, were more ductal than iron, and could be formed into tubes. The use of tubing made for a lighter frame and fork. Strong steel wire replaced wood for wheel spokes. Advances in steel technology lead to the cup and cone ball-bearing, and British imperialism led to the India rubber tire. The first led to a smooth running machine, and the second dampened the vibration and jarring of an iron tire. By the 1870s what we now call the “Ordinary” bicycle had replaced the bone-shaker. The lighter, smooth running gear meant that the front wheel size was limited only by the rider’s leg length. To utilize a bigger front wheel, the rider position moved so far forward that the rider’s center of mass was only slightly behind the wheel center. This is great ergonomically but in practice, anything impeding the front wheel could send the rider over the handlebars. To add injury to insult, the handlebars tend to trap your legs, so you are going all the way to your hands, unless skilled enough to do a shoulder roll. Then, as often as not, the machine then jumps on top of you. Still, a good wheelman, on good roads, could cover 100 miles in a day.

This time period saw great advances in technical possibilities. Butted tubing, thicker on the ends than in the middle, could be drawn. Tubes could be tapered. Bicycles used all of this. By the mid ‘70s a well-made wheel for fast work could be had that weighed around 24 pounds. Another innovation brought about by bicycle-building was the standardization of parts. People could order a replacement part and, with a little mechanical skill, install it themselves. Parts did not have to be custom-made or fitted to the wheel. This is near universal today, and it all started with bicycles.

Bicycle innovation took a major leap forward with the development of the roller chain. Although Leonardo da Vinci had drawings for a drive chain and slow-speed bucket chains were used for lifting water, their application to cycles didn’t happen until the 1880s. Again, it was the advances in steel, and its workability, that made the difference. The first chain drive I am aware of was brought out by Messrs. Hillman, Herbert and Coper in 1884. Built like an Ordinary, with the cranks placed below the wheel center, and a driving chain on each side connecting the cranks with the wheel. Two things became apparent: a smaller, lighter wheel could be used, and the crank length could be maximized to the rider. Indeed, on Sept. 27, 1884, Mr. G. Smith covered a 100-mile course in 7 hours, 7 minutes, 11 seconds, a world record at the time.

The next few years saw huge changes in bike design. The advent of gears allowed for a host of configurations. At first many frame arrangements used curved tubes, as had the Ordinary. The crank axle could be lowered and placed between the wheels. The rear wheel then did the driving while the front wheel did the steering. Under no size constraint, wheels settled at around today’s 28 inches. Curved tubes disappeared, except for the ends of the front fork. The extra flex of curved fork blades helped absorb road jar. By 1890, when Messrs. Humber and Co. brought out their rear driving safety with diamond frame, we had arrived at the bicycle we know today – all straight tubes with curved fork blades and chain drive. 1890 also saw the last great innovation in cycle design when Mr. James Dunlop of Dublin made the first pneumatic tire for his son. Within only a year, 40 percent of bikes were riding on air, as the Dunlop Company would later claim.

Of course, the top tube on the early bikes presented problems for Victorian-era women whose wardrobe usually consisted of large skirts. One solution was the advent of the bloomer, as long baggy pant that narrowed to a cuff at the ankles allowing women to straddle a horse, swim or ride an Ordinary. Eventually the top tube on the bike was dropped, allowing for ladies to ride in a skirt and still maintain the dignity required of the times on what is referred to as a step-through frame.

To call the 1895 Humber the bicycle of today is as true as calling the Model A Ford the car of today. Everything is there, but the “ride-ability,” like the “drivability” of the Ford, has been much refined. All crank bikes to that point were fitted for direct drive. No coasting. If the machine was moving, so were the cranks. This arrangement is still used today by some. To slow down, you ease up on the cranks. This set-up still produces the cleanest, most pure bicycle. No brakes required, only one gear. Called a fixed-wheel or fixed-gear, and lately a “fixie,” such bikes are preferred by big-city messengers. I myself choose one for slick roads because of the instant response. Not everyone does. For everyone else, the coaster brake was developed, providing for coasting, and incorporating a brake activated by moving the cranks backward. Many town bikes are set up this way.

The high-speed boys, known as ‘scorchers,’ wanted more. It was found that the chain could be made to jump from one cog to another and three different ratios could be had. A little more tinkering and five rear cogs with two chain-rings became standard. This is the ten-speed. Today we are up to nine cogs and three chain-rings. Although a derailleur system is the lightest and most efficient, all that gear is out in the open, collecting dirt and water, and vulnerable to damage. Others, working up from coaster brakes, developed a design using planetary gears inside the rear hub to give different ratios. One planetary gear set will yield three speeds. Everything but the shifting chain is inside out of the weather, an excellent choice for an all-weather commuter.

Brakes, used to some extent even in the Ordinary days, have also evolved. The early “spoon” brakes worked by pressing against the front tire. They didn’t work very well, but that was an advantage on an Ordinary. A powerful brake would have your nose headed straight for the ground. A bicycle that coasts is entirely dependent on its brakes. Better designs were needed. Brakes that worked against the rim were developed to avoid damage to the more fragile pneumatic tires. Brakes acting on the rim make sense because the rim is already there. The disadvantage is being out in the open. They don’t work well in wet weather, and can stop working completely in freezing rain. For those conditions, hub brakes are popular. Both internal, expanding drum, and external, contracting band, brakes are used. Nowadays we are seeing more disk brakes. Rim brakes are always lighter, work well enough, and besides, brakes make you go slow. I wanna go fast!

Now we’ll take a look at some special-purpose bicycle adaptations. As we have seen, wheel size has hovered around 28 inches for an adult machine. It’s a size that fits the human body rather well. It does make for a fairly large machine though, as anyone who has tried to transport one in a small car knows. In soft or rough conditions, a bigger wheel has a clear advantage. On today’s hard, smooth roads however, the advantage largely disappears. Today a compact small-wheel bike can be had that gives up very little. Folding designs reduce the size even more. Such a bike works well for people using public transport or flying in small planes. Another design that has been around a long time is the recumbent. The rider position is mostly unchanged, but rotated back until the spine is mostly vertical and the legs more horizontal. It’s somewhat like sitting in a sports car. The advantage is a lower center of gravity, and reduced frontal area. The biggest disadvantage is that the cranks and front wheel need to be in the same place. If the front wheel is moved forward enough for clearance, the machine gets quite long and the front to rear weight balance is heavy to the rear. If the front wheel is moved back, the front end is heavy and the steering gets awkward. The other disadvantage is that a recumbent is hard to spot. This is a major issue when sharing the road with plesianthropus celphoni in a two-ton SUV.

So, what are all of these bikes made of? Wood was the early favorite and still makes a good rim if rim brakes are not used. Some beautiful bikes have been made from bamboo, but steel tends to get the most use. It makes a fine bike, can be straightened and repaired ,and has a firm feel. However, steel does rust and aluminum does not. Aluminum, though, is not nearly as strong. It can’t be easily straightened well. This means that a broken aluminum frame is nothing but junk. Fortunately, when one breaks in two, you can put it out with the beer cans. Aluminum frames also have a different, kind of “dead” feel. But aluminum is a good choice in other bike parts such as rims.

Another frame material is titanium. The feel is more like steel. It can be welded and straightened some, and doesn’t rust. It’s quite costly though, and the welding techniques add even more expense. Also, today we are seeing a lot of carbon fiber frames. In these, the very strong carbon strands are woven and held with a resin, much like fiberglass. When a carbon frame breaks, though, it is almost always landfill material. Plastics have been tried some but so far, lack much of a following. So, which to choose? It depends on both your wants and pocket depth.

Just as no red-blooded Western man could conceive of only owning only one rifle, be prepared to own several bikes. That way, you can always choose another if the one you were planning to ride has a flat. Seriously though, a town bike with a low “theft ratio” is safer to leave unattended and will take wear and tear off of your high-performance bike. It can be fitted with racks or bags for carrying things, and generally you will be wearing out much cheaper tires and equipment. Today, bikes can be had that use lowered cranks and a more relaxed, upright seating position. This makes it easy to put a foot down, and could be perfect for herding grandkids down the bike path. Bikes for off-road use generally have higher cranks. This keeps you from hitting your pedals at the cost of a higher center of gravity. A high-speed road bike will have a rider position that puts your torso nearly horizontal, to keep you out of the wind. Pushing the wind aside takes about 80% of your energy at racing speeds.

Figure out your needs and wants and try out a bunch of bikes. Then you, too, can have better health while avoiding costly foreign oil. g

Local anarchist and ne’er-do-well Eric Sampson lives in Hollywood (the other one …).