by Jackie W. Powell

Photos courtesy of The Salida Library

People say “Soft Salida brick” as if it were one word. Many believe it was sun-dried, like adobe, and therefore not as hard as fired brick. The myth of sun drying is reinforced by photographs such as Figure 1 , showing thousands of bricks lying in the sun. But this was only one of the five steps needed to transform clay into fired bricks: mining, tempering, molding, drying, and firing.

A brickmaker looked for clay deposits with good texture and color. Ideally they were near the surface, to be easily accessible. At least one Salida brickyard operated where clay deposits existed, said to be on County Road 107 on the way to Woodlawn Cemetery.

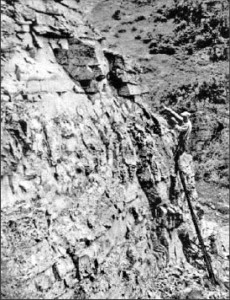

By 1880, when Salida was founded, technology had advanced enough that not all the brick making drudgery was done by hand labor. Although the steam shovel was invented in 1879, such expensive machinery was not used in Salida brickmaking. If it was found in wide swaths at the surface, a layer of clay might be excavated by horse-drawn scrapers like ones that were used to build railroad beds. In Figure 2, it appears that in Salida a bank of clay was exposed and then pulled down by hand tools.

Historically, clay was dug in autumn so it could be left to weather over the winter. The freeze-thaw would break it down so it would be soft and could be more easily worked by hand. Unwanted oxides would also leach from the clay during winter. The brickmakers were interested in letting nature process the clay as much as possible, because the next step was to prepare it for molding. Preparation originally involved mixing the clay with water in a pit and kneading it with hands and feet to obtain the right consistency. Called tempering or pugging, this was the hardest work in the brickmaking process. Horse-powered pug mills like the Salida one seen in Figure 2 were invented in the mid-nineteenth century. Not only did this reduce labor, it also reduced the need to allow the clay to weather over the winter.

Once the clay was tempered to a good consistency, the workers removed it from the pit and took it to the molding table. Here, a clot molder prepared a lump of clay, known as a clot, and handed it to the molder. The molder rolled it in sand, and “dashed” it into the mold, which was wet and had also been sanded. The sand prevented the brick from sticking to the mold, making it easier to remove for drying.

Each mold had space for up to six bricks. In Salida, the barrows seen in Figure 2 were used to carry several molds at once.

Possibly, the flat-bedded barrows seen in Figure 2 were used in place of stationary molding tables. This would allow the bricks to be molded at the pug mill and then removed to the drying area without having to transfer the molds from a table to the barrow. After the bricks were removed from the molds to dry, the molds were returned to be wetted, sanded and refilled.

Eleanor Fry, in her book, Salida:The Early Years, says, “Clay was packed into three-brick molds which were then dumped on the ground in long rows to sun dry.” All the photographs of the Salida brickyard show the bricks drying on a narrow side. Having the narrow side down would expose the largest possible surface to the air. They are arranged in three rows, which is logical if they were dumped from three-brick molds before being arranged on edge to dry.

The bricks were turned to be sure they dried evenly and didn’t warp. Turning could be done by children. During the time the bricks lay in the sun before being turned – “tools called dressers or clappers were used to straighten the bricks and obtain a smooth surface.”

In some cases, the bricks would be stacked on end in a herringbone pattern, and left to dry further. Ricks-Bricks describes how these were often covered, to protect them from “rain or the harsh sun.” None of the photographs of the Salida brickyards show bricks stacked this way, nor covered. In Salida’s arid climate, this step in the process was probably unnecessary, and the sun-dried “green” bricks reached a low enough water content to be moved directly from the initial arrangement to the kiln.

From Ricks-Bricks:

![Salida-Brickmakers-2 Figure 1. This photograph is published In Eleanor Fry’s Salida: The Early Years. There, the caption reads “Clay was packed into three-brick molds which were then dumped on the ground in long rows to sun dry. This unidentified boy may have been responsible for [turning] the thousands of bricks drying.”](https://coloradocentralmagazine.com/wp-content/uploads/2009/10/Salida-Brickmakers-2.jpg)

If fired bricks were on hand they were used to construct the outer walls of the kiln and the surface was daubed with mud to contain the heat. If no fired bricks were available the kiln was constructed entirely of green or raw bricks which were stacked in such a way as to act as their own kiln. These kilns were called clamps or scove kilns. Wood and coal were used for fuel.

There is no photographic evidence that the Salida brickyard plastered its kilns, but it is possible that the photos were taken between firings.

The firing process would take about two and a half weeks. The fires were kept low for the first day or two to help remove the remaining water content. If the kiln was fired too high too soon, the bricks could explode. Steam coming out of the kiln signaled that water was burning off and when the steam stopped it was time to increase the heat. Then, according to Ricks, “intense fires were maintained in the fire holes around the clock for a week until temperatures of 1800 degrees F were reached.”

This required an enormous amount of wood or coal. At the Salt Works Ranch in South Park, CO, 700 cords of wood were kept on hand to provide the heat necessary to boil the saline in enormous salt pans. Profit from making salt decreased according to how far away wood was, and timber stands became depleted at ever-increasing distances.

Perhaps in Salida there was a cheap supply of coal brought in by the railroad. Initially there was a good supply of piñon and juniper nearby and many taller trees stood not very far away on the slopes of Methodist Mountain. Piles of what appear to be fuel wood can be seen behind the kilns in one picture in the Salida Library archives not included here.

Once the brickmaker decided the bricks were adequately fired, the fuel holes would be bricked over, and the kiln would be allowed to slowly cool for another week.

Again, from Ricks-Bricks:

When the kiln was disassembled the sorting process began. If only raw bricks were used, the bricks from the outermost walls were kept to be burned again in the next kiln. Some bricks which were closest to the fire received a natural wood ash glaze from the sand that fell into the fires and became vaporized and deposited on the bricks. These bricks were used in the interior courses of the walls. Bricks that became severely over burned and cracked or warped were called clinkers and were occasionally used for garden walls or garden paths.

The best bricks were chosen for use on the exterior walls of the building. Those that were only slightly underfired had a salmon color and early bricklayers knew that the porosity of these bricks would help to insulate the structure and they were placed on the innermost courses of the wall.

Sometimes, to protect under-fired brick exposed to the weather, a “color wash” made up of glue sizing, pigment (iron oxide), and potash alum was applied to the brick, and the mortar was painted white. This technique may have been used on some of Salida’s buildings.

Harder-fired bricks from sources such as the Pueblo Brick Company soon became cheaply available by railroad, making a wider range of types and colors of brick available. The Rio Grande Hospital, built in 1885, is of buff brick. The 1890 Twitchell Building displays brick of a darker color and with more inclusions than in Salida-made bricks.

Any brick, hard-fired or soft, deteriorates when there are water problems – improper drainage from the roof, improper foundation grading that allows snow and water to sit against the building. Additionally, when walls of this soft brick are repointed with mortar that is too hard, possibly because it is made with a high cement to lime ratio, the difference in the ways the soft brick and hard mortar react to moisture and temperature will cause the brick to spall, crack, and sometimes break.

More and more of our unique Salida brick is being covered with stucco or paint. The design guidelines for the Salida Downtown Historic District prohibit application of paint or stucco to brick that is not already covered with these materials. This is not only because the goal is to preserve the historic character of downtown, it is also because these actions can cause damage.

When deteriorated brick is covered with stucco that doesn’t breathe, moisture problems can be sealed in and cause the walls to deteriorate even more quickly. Paint is often applied for aesthetic or falsely hopeful “low-maintenance” purposes. In many cases, the paint quickly begins to peel and the building owner is faced with having to repaint more frequently. Anyone purchasing a brick or brick-veneer building in Salida that has stucco or paint on the brick should be careful that it was applied solely for aesthetic purposes, and not simply to cover up structural or masonry problems.

Cleaning any brick can destroy it. Soap and water used with a soft brush is the most desirable cleaning treatment. Rarely, with certain types of harder brick, power washing might be appropriate. Using harsh methods such as acids, sandblasting, or blasting with nutshells will remove the protective outer coating provided in the firing process, and cause it to be even softer and more porous than it was originally. These methods will also harm the mortar, and repointing might be required.

But does it really matter if an old building shows a its usage through a few flaws and flecks? We wouldn’t have wanted Mother Theresa to get a facelift, so why do we want our old buildings to look brand new?

Salida brick is similar to other brick made and used in early Colorado. Larimer Square in Denver, Georgetown, Central City, Cripple Creek are a few examples. These buildings have stood for over a hundred years and, with proper maintenance and repair, will stand for another hundred. We should be proud that we have so many lovely brick buildings in Salida. They communicate a natural elegance that is difficult to surpass.

After 30 years of working in historic preservation with the National Park Service and as a consultant, Ms. Powell now serves on local and state boards and commissions that work to preserve our threatened historic resources. She and her husband retired to Salida because of its historic character and excellent fly fishing.

Works Cited:

Bonomo, Rick. Ricks-Bricks: The Fine Art of Hand Brickmaking ca. 1850. http://www.shol.com/agita/thespiel.htm (accessed June 7, 2009).

Fry, Eleanor. Salida: The Early Years. Edited by Dick Dixon. Salida, Colorado: Arkansas Valley Publishing.

Salida Regional Library Local History Archives. Archival Holdings: Photographic Collections: The Salida Centennial Photo Archive, Book 1. http://salidaarchive.org/photo/book1/index1.html (accessed June 7, 2009).

Simmons, Tom and Laurie, Colorado Salt Works National Register Nomination, Front Range Research Associates, 2000.